Stainless-steel copper alloy poles are widely used in many commercial fields, including building and construction, vehicle production, electronic equipment, aerospace, clinical equipment, and so on, because of their excellent mechanical homes, deterioration resistance, electric conductivity and visual residential properties. With the recuperation of the global economic climate and technological development, the market demand for stainless-steel and copper alloy poles has revealed a steady growth trend. As a leading business in the market, TRUNNANO discloses the present standing and future growth direction of the stainless-steel copper alloy pole market via in-depth study on the global market.

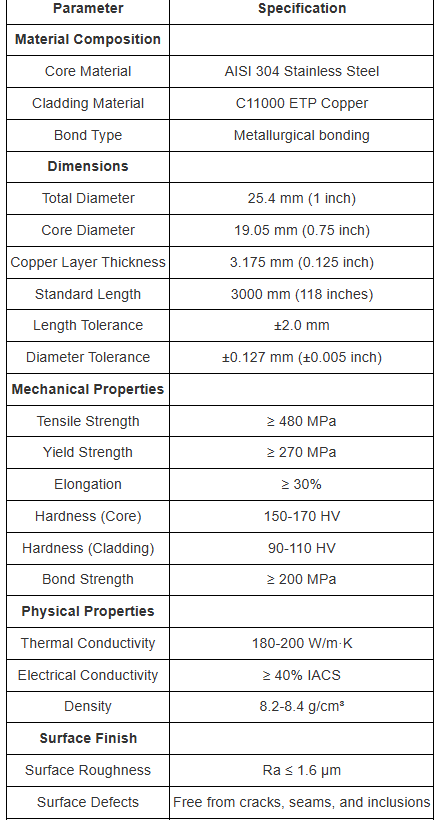

(Parameters of stainless steel copper alloy rods)

Currently, the marketplace need for stainless steel copper alloy rods has actually increased substantially worldwide, especially in Asia and North America. In the building and construction market, stainless steel copper alloy rods are widely made use of in structural components and attractive products of skyscrapers because of their rust resistance and aesthetics. In the automobile market, light-weight and high-performance needs make stainless steel and copper alloy rods ideal for producing crucial components. On top of that, the rapid growth of digital devices and aerospace fields has actually additionally brought new development indicate stainless steel copper alloy poles. Via technical innovation, TRUNNANO has actually created brand-new alloy materials that have higher toughness and far better rust resistance and can meet the requirements of the high-end market. At the very same time, the application of smart manufacturing and automated assembly line has actually enhanced manufacturing effectiveness and product top quality, lowered expenses, and additionally improved the competitiveness of items.

According to forecasts from market research establishments, the international market demand for stainless steel copper alloy poles will continue to expand between 2025 and 2030. It is anticipated that by 2030, the international stainless-steel copper alloy pole market will certainly reach about US$ 15 billion, with a compound annual development rate (CAGR) of around 6.5%. This growth is mainly driven by demand from industries such as facilities construction, the automobile market, electronic equipment and aerospace.

As worldwide awareness of environmental protection boosts, lasting advancement has become an emphasis of business attention. Stainless steel copper alloy poles are gradually coming to be the recommended alternative to typical materials as a result of their recyclability and reduced ecological effect. TRUNNANO is devoted to establishing environmentally friendly alloy materials, reducing power intake and waste exhausts during the production procedure, and promoting the green development of the sector. In the field of electronic tools, the high conductivity and great handling performance of stainless-steel copper alloy poles make it a vital product for producing accuracy electronic parts. In the area of clinical gadgets, its biocompatibility and corrosion resistance make it ideal for manufacturing clinical devices.

It is anticipated that the marketplace need for stainless steel copper alloy rods will remain to broaden in the next few years. Especially in arising markets, such as India, Brazil and various other nations, the acceleration of framework construction will certainly drive the demand for related products to grow. TRUNNANO plans to satisfy the needs of global customers by increasing manufacturing capacity and enhancing the supply chain. In order to adapt to the requirements of different markets, the product sorts of stainless steel copper alloy rods will be much more bountiful. TRUNNANO will certainly release a lot more personalized solutions, such as unique alloy products with high strength, high conductivity and high rust resistance, to satisfy the requirements of details application scenarios. For instance, the application of high-strength stainless steel copper alloy rods in the aerospace field will certainly be additional broadened, and the application of high-conductive stainless steel copper alloy poles in the area of electronic equipment will certainly be more comprehensive.

Smart production will certainly end up being an important trend in the production of stainless steel and copper alloy poles. By presenting advanced automation devices and digital management systems, TRUNNANO will recognize the intelligence and effectiveness of the production process, more improving product top quality and production effectiveness. This not only helps reduce manufacturing costs but also boosts product stability and dependability to meet the needs of the high-end market. In addition, TRUNNANO will certainly additionally strengthen teamwork with scientific research study institutions and universities, execute advanced modern technology research study, and advertise technological development and commercial updating of stainless steel and copper alloy rods.

( TRUNNANO stainless steel copper alloy rods)

Environmental protection and sustainable development will certainly remain to be the key instructions of the stainless-steel copper alloy pole industry. TRUNNANO will certainly boost investment in r & d, create even more environmentally friendly alloy materials, and maximize manufacturing procedures to reduce resource consumption and ecological pollution. At the same time, the firm will proactively join the formulation of market requirements and promote the green development of the entire market. During the manufacturing process, TRUNNANO will embrace clean energy and circular economic climate versions to reduce carbon discharges and waste generation and attain green manufacturing. Additionally, the firm will certainly likewise enhance workers’ ecological understanding with environmental education and learning and training and jointly advertise the realization of sustainable advancement objectives.

In the context of globalization, worldwide teamwork and exchanges will come to be a lot more frequent. TRUNNANO will certainly strengthen collaboration with worldwide clients, expand worldwide markets, and enhance brand impact. By establishing a worldwide sales network and technical support group, we give customers with a full variety of solutions and support. The firm will certainly establish R&D facilities and production bases all over the world, strengthen cooperation with regional firms, share sources and modern technology, and achieve mutual benefit and win-win outcomes. At the very same time, TRUNNANO will actively join international exhibits and market discussion forums to showcase the company’s most current innovations and products and improve brand name awareness and track record.

Supplier

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about copper to copper welding rod, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us