Gypsum Retarder Sodium Citrate

High Performance Slump Retaining Admixture Polycarboxylate Superplasticizer PCE Liquid 50%

Water Proof Concrete Superplasticizer Admixtures TC 7070WR Helps To Retains Workability

YJ-40 High performance efficient environmentally foaming agent for concrete

Defoamer Antifoam Food Grade Anti Foaming Agent For Soybean And Milk

Sio2 Nano Fumed Defoamer Concrete Admixture Powder Coating Application Defoamer Antifoam

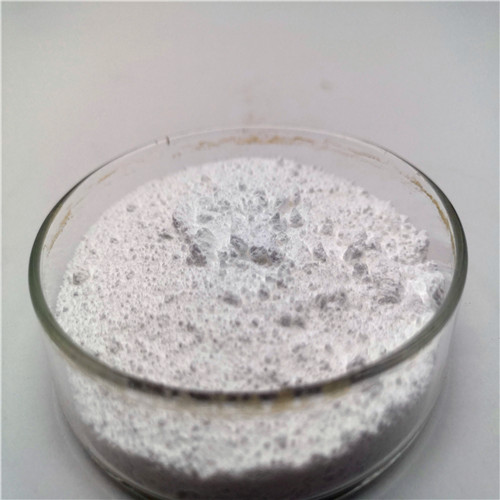

Overview of Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop

Aerogels are ultralight, highly porous materials known for their exceptional insulation properties, remarkable low density, and incredible strength-to-weight ratios. Often referred to as "frozen smoke" due to their ethereal appearance, aerogels are produced by replacing the liquid component of a gel with gas, typically through supercritical drying, which avoids collapse of the gel structure. Composed primarily of air (up to 99.98%), these materials exhibit a wide array of unique characteristics that make them valuable across various industries.

Features of Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop

Extremely Low Density: Aerogels are some of the world's lightest solids, with densities as low as 0.001 grams per cubic centimeter.

Superb Insulation: They possess extremely low thermal conductivity, making them among the best insulators known to man, effective at temperatures from -270°C to 1,000°C.

High Porosity: With a porous structure that can reach up to 99.9%, aerogels have an incredibly large internal surface area, enhancing their functionality in absorption and catalysis applications.

Translucent to Transparent: Depending on their composition, aerogels can transmit light, giving them a unique semi-transparent or transparent appearance.

Mechanical Strength: Despite their fragile appearance, aerogels can be engineered to possess significant mechanical strength, capable of bearing considerable weight.

Chemically Inert: Many aerogels are chemically stable and resistant to corrosion, making them suitable for harsh environments.

(Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop)

The production of insulation aerogel silica-aerogel pulver aerogel can be parameterized using various factors, such as the purity and particle size of the silica particles, the presence of impurities in the preparation process, the temperature range of operation, and the specific application requirements. Some common parameters used to describe the performance of insulation aerogel silica-aerogel pulver aerogel include: * Air permeability: This is a measure of how well the aerogel performs at allowing air to flow through it. * Density: This is the mass per unit volume of the aerogel. * Porosity: This is the percentage of open spaces or gaps in the aerogel that allow air to pass through. * Thermal conductivity: This is the rate at which heat transfer occurs within the aerogel. These parameters can be influenced by various factors during the production process, such as the type of silica particles used, the drying method used, and the temperature range of operation. By controlling these parameters and optimizing the production process, it is possible to produce insulation aerogel silica-aerogel pulver aerogel with the desired properties for various applications.

(Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop)

Applications of Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop

Thermal Insulation: Used in aerospace for spacecraft insulation, and in commercial and residential buildings for energy-efficient windows and insulation materials.

Environmental Remediation: Aerogels' high surface area makes them effective in absorbing pollutants like oil spills and heavy metals from water.

Sound Absorption: Their porous structure absorbs sound waves effectively, making them useful in noise reduction applications.

Electronics: Aerogels' low thermal conductivity and electrical insulation properties find applications in semiconductor and battery technology.

Optics and Photonics: Translucent aerogels are used in optical devices, light-guiding structures, and as filters.

Drug Delivery: The high surface area can be utilized for controlled drug release, making aerogels candidates for advanced medical applications.

Cie-China is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality concrete additives and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality concrete materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

L/C, T/T, Western Union, Paypal, Credit Card etc.

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop

Q: Is Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop fragile? A: Traditional aerogels are brittle and fragile; however, advancements have led to the development of "flexible" or "rigid" aerogels that maintain their unique properties while being more durable.

Q: How is Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop made? A: Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop is synthesized by replacing the liquid in a gel with gas without causing the structure to collapse. This is typically achieved through supercritical drying, where the solvent is converted to a supercritical state, allowing it to evaporate without forming liquid-gas interfaces that could damage the gel structure.

Q: Is Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop expensive? A: Historically, aerogels have been costly due to their complex manufacturing process. However, with technological advancements and economies of scale, costs are gradually decreasing.

Q: Can Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop conduct electricity? A: Most aerogels are poor conductors of electricity due to their porous, insulating nature. However, certain metal-oxide aerogels can display semiconducting or even conducting properties.

Q: Is Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop environmentally friendly? A: Aerogels themselves do not pose environmental hazards, and their use in insulation can reduce energy consumption. However, the production process may involve chemicals that require careful handling and disposal.

(Production of Insulating Aerogel Silica-aerogel Pulver Aerogel Te Koop)

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.